Doctor, can you print me up some new skin, mine is burned.

Sometimes, the technology of 3D printing almost seems too incredible to believe. The idea of printing three-dimensional objects sounds more than a little far-fetched. There is nothing impossible about the science, however. A deeper understanding of how the process works, coupled with a more technical description of this amazing advancement, does much to shed some much-needed light on this advanced manufacturing process.

The Science Behind the Process

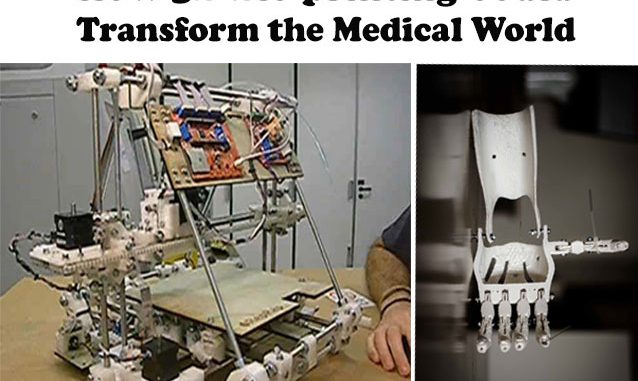

The term “3D printing” can be a bit confusing, and does not quite adequately describe the process. To get a clearer idea of how 3D printing works, think of it as additive manufacturing. While the materials used in 3D printing vary dramatically from one project to another, the process does not. First, a computer file is loaded into the 3D printer. This file can be a computerized 3D model or other computerized schematic, such as a specialized document known as an additive manufacturing file.

Once the computer has a model of what it is creating, it begins synthesizing and printing one layer after another. A three-dimensional object is then constructed by layering and fusing individual sheets together until the computer model has been recreated in the physical world.

This is, of course, a simplified explanation of a thoroughly complex process, so much so that describing it as a single process is a misnomer in itself. 3D printing technology is used in a variety of fields, from the construction of automotive parts to robotic machinery. Specifically, there are seven different established methods of accomplishing 3D printing.

3D printing has made countless advances since its invention in the 1980s, but the concept is nothing new. In truth, neither is the idea of printing biological matter. But the implementation of bio-3D materials has been beyond the reach of scientific understanding.

All that is beginning to change.

New Developments:

Independent studies of bio-printing are ongoing at a variety of universities. Two universities have recently made significant advances in advancing the technology, inching bio-printing ever-closer not only to theoretical reality, but towards practical reality as well.

The first development was made at the University of Bristol. Led by Dr. Adam Perriman, the researchers at Bristol developed a revolutionary type of bio-ink that incorporates stem cells with both synthetic and natural polymers to print biological tissue structures.

This bio-ink is made possible by its synthetic polymer. As the temperature of the bio-ink increases, the liquid polymer changes state to form a solid. As cell nutrients are introduced to the bio-printing, the natural polymer – an extract from seaweed – supports the structure of the material.

Describing the development of the bio-ink, Dr. Perriman was honest. “Designing the new bio-ink was extremely challenging. You need a material that is printable…that is not harmful to the cells. We managed to do this, but there was a lot of trial and error.”

What was truly impressive about this achievement was the printed tissue’s response to the synthetic polymer. Perriman continues, “When the cell nutrients were introduced, the synthetic polymer was completely expelled from the 3-D structure, leaving only the stem cells and the natural seaweed polymer.” This further strengthened the bio-print as it continued to develop and provide nutrients for the stem cells.

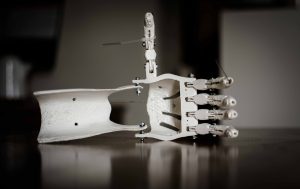

The hope is that, as this bio-printing technique continues to develop, that it could be used to eventually print far more complex tissues, using stem cells from a patients’ own body to repair their knee or grow a new long. If the technology continues to progress, it could eventually eliminate the need for organ donors entirely.

Such advances are still years and decades away, but another innovative discovery was announced just weeks ago. Studies at the Universidad Carlos III de Madrid have developed the prototype for a 3D bioprinter capable of printing biologically compatible human skin.

A Major Breakthrough

There is a great demand for human skin. At present, it is technically difficult to acquire the skin necessary for medical transplants. Skin donations are hard to come by, and the process is unpleasant for both parties.

There is a great demand for human skin. At present, it is technically difficult to acquire the skin necessary for medical transplants. Skin donations are hard to come by, and the process is unpleasant for both parties.

This new technique of skin printing creates biological tissue that replicates the natural skin structure, complete with both dermis and epidermis. The skin can be printed by stem cells taken from the intended recipient of the skin graft, improving the likelihood that the body will accept the graft.

In addition to its usage in restorative surgery, this printed skin tissue can also be used to test chemical, cosmetic and pharmaceutical products for their reaction to skin tissue, which could lead to new developments in both aesthetic cosmetics and pharmaceutical skin creams. It is also possible that this breakthrough will advance other forms of research, and may help to facilitate the printing of other biological structures.

While the field of bio-printing is still early, it is already yielding promising results. Only time will tell what other advances may yet be witnessed.